Rotating Die Units

Rotating die holders are a very easy way to increase productivity and reduce die wear on wire drawing lines.

The die itself is continuously being cooled by means of re-circulating water around the die as the die

rotates around the wire during the wire drawing operation. Lubrication boxes are also provided to hold dry

or liquid lubricants.

Advantages over Stationary Die Units are :

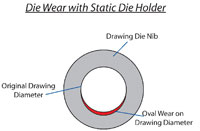

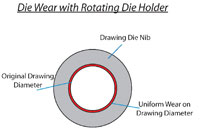

- Longer die life - slower & even die wear

- Less wire breaks - cooler drawing temperatures

- Less maintenance down-time

- Eliminates oval die wear – higher wire tolerance

- Reduce drawing temperatures

- Improved lubrication of wire

- Improved Wire finish - less wire scarring

- Faster line speeds

|

|

Rotating Die Unit

- Manufactured according to production requirements

- Motorized or with roller pulley rotation

- Available in fast or slow rotation

- Able to house 1 or 2 dies for a pressure die system

- Models to accommodate variety of die sizes

- Various sizes of lubricating boxes

- Liquid emulsion lubricant lube boxes

|

|

Standard Die Holder Model-Sizes

- FA10: 1.5" up to 2" die OD

- FA63: Up to 2.5" die OD

- FA100: Up to 3.5" die OD

|

|

Special Indirect Cooling

- Die is indirectly cooled through a special re-circulating mechanism

- This system avoids maintenance issues with leaky gaskets

- Avoids possibility of seizing the rotating mechanism due to leaks

|

|

Polished Wire Finish Unit

- Special unit with immersed die holder

- Double drawing pass in 1 unit

- Grease or oil filled lubrication box

- Finished wire exits shiny and polished

- Ideal for nail & fastener manufacturing

|

|