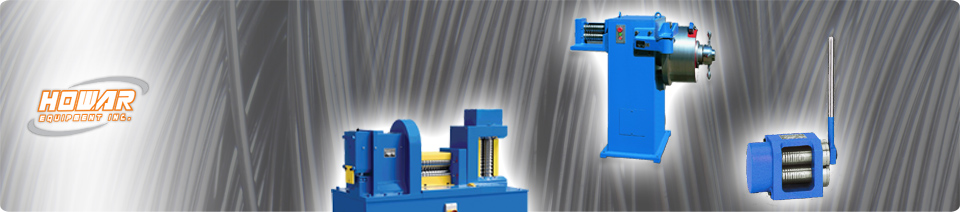

Wire Pointers, Wire Shaving and Wire Feeding

Wire pointers used for setup of wire /bar drawing machinery is manufactured to the highest

quality and durability. Precision ground rollers and tooling ensure effective long term

pointing applications, ensuring operator safety and ease of use.

Hand Roller pointing machines: HSM

- Smaller diameter pointing of wire

- For ferrous and non-ferrous materials

- Precision hardened and ground forming rollers

- Various diameter working range available

- Easy hand lever operation

- Up to 4 mm (0.16") max diameter

|

|

Pointing and string-up machines: EZM

- Pointing and string-up of drawing dies

- Pull-in capstan individually powered

- String-up multiple dies at once

- Precision hardened and ground forming rollers

- Various diameter working range available

- Quiet and minimal vibration operation

- Safe and easy to use

- Wire cutting equipment available

- Up to 14 mm (0.55") max diameter

|

|

Motorized Roller pointing machines: DSM

- Heavy duty pointing of wire/rod

- Round, square, or shaped materials

- Ferrous and non-ferrous materials

- Precision hardened and ground forming rollers

- Various diameter working range available

- Quiet and minimal vibration operation

- Safe and easy to use

- Wire cutting equipment available

- (+V) horizontal + vertical pointer assembly

- Up to 32 mm (1.26") max diameter

|

|

Hydraulic swivel roller pointers, Type HSM

- Designed for confined spaces

- Pointing roller assembly rotates 90 degrees

- Hydraulically activated roller assembly rotation

- Point both vertical + horizontal wire axis

- Up to 45 mm (1.77") max diameter

|

|

Shave Pointing Machines: ASM

- Large diameter pointing

- Rounds, squares, hexagons

- Ferrous and non-ferrous materials

- Create any configuration point

- Use cutting head to create point

- Used commonly on coil-to-coil drawing

- No tooling special tooling needed

- Replaces costly swaggers

- Reduce up to 6 mm (1/4") each shaving pass

- Up to 150 mm (6") max diameter

|

|

Straightening & Feeding Equipment

- Powered straightening rollers

- 3 or 5 straightening rollers

- For in-feeding of pointers

- Pinch roller feeding assembly

- Designed for application

|

|